Applications Cases

Applications Cases

Applications Cases

사례설명

Application Case

Applications Cases

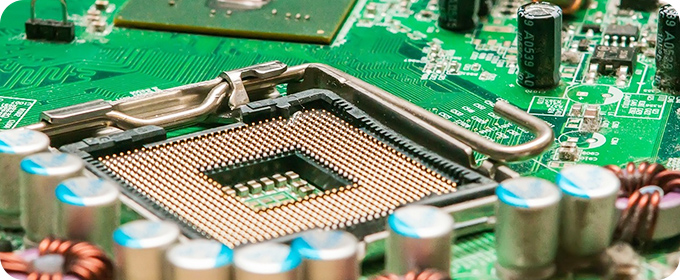

Instrumented indentation testing is widely used across various industries and research institutions to measure the mechanical properties and residual stresses of materials, from large structures to thin films, at macro, micro, and nano scales.

This technology offers superior local property analysis compared to traditional testing methods, providing fast, convenient, and accurate measurements.

Frontics' instrumented indentation testing technology plays a crucial role in material inspection, quality assessment at various production stages, process improvement, and product quality control in a wide range of industries. It is also extensively used for equipment safety evaluation, material degradation life assessment, and damage analysis.

This technology offers superior local property analysis compared to traditional testing methods, providing fast, convenient, and accurate measurements.

Frontics' instrumented indentation testing technology plays a crucial role in material inspection, quality assessment at various production stages, process improvement, and product quality control in a wide range of industries. It is also extensively used for equipment safety evaluation, material degradation life assessment, and damage analysis.

Directions

Directions